What Is Internet of Things Monitoring Software?

Monitoring software for the Internet of Things (IoT) is a collection of specialized applications and tools that help keep tabs on, manage, and analyze data from IoT devices.

Customers get up-to-the-minute data, remote performance monitoring, and anomaly detection with these solutions.Discover how Internet of Things monitoring software powers intelligent networking. Learn how these tools ensure seamless IoT device performance, enhance security, and drive efficiency in smart systems.

This is of the utmost importance in environments with many networked devices, such as smart homes, factories, healthcare facilities, and public transit systems.

Why Is It Crucial to Monitor the Internet of Things?

The components of an IoT system, including sensors, devices, and data flows, need constant vigilance.

Any problem with one device may affect the whole network.

Through the detection of early warning signs of problems, monitoring improves system reliability and performance.

Key Attributes of IoT Monitoring Software

-

The term “real-time analytics” describes the process of quickly accessing data streams taken directly from IoT devices.

-

Device status alerts notify users when a device overheats, goes offline, or displays unusual behavior.

-

Graphs and dashboards are examples of data visualization, which helps to simplify otherwise difficult-to-understand device statistics.

-

With remote control, users may power cycle devices or adjust their settings from a distance.

-

Capabilities for Integration: Connects to other applications, cloud services, and APIs.

An essential part of the software and sensors used for Internet of Things monitoring is the hardware that collects data and sends it to the program.

Devices on the ground may communicate with servers in the cloud or data centers via gateways.

For future use, the cloud stores massive amounts of data created by devices.

The term “user interface” (UI) is used to describe web or mobile apps that allow users to interact with the system.

Risks Not Sufficiently Monitored

-

Potential safety hazards or production delays might arise from equipment breakdowns that go unreported.

-

Data leaks caused by dangerous device activities may violate user privacy.

-

wasting energy when devices are kept on for long periods of time without being used.

-

When interconnected systems suffer unanticipated outages, businesses must bear the cost of downtime.

How Internet of Things Monitoring Software Works

Devices provide information to a hub via cellular networks, Bluetooth, or Wi-Fi.

The software applies AI and ML to this data in order to spot outliers.

Users are notified by visual reports, alerts, or automated triggers based on specific criteria.

Use Cases in Different Industries

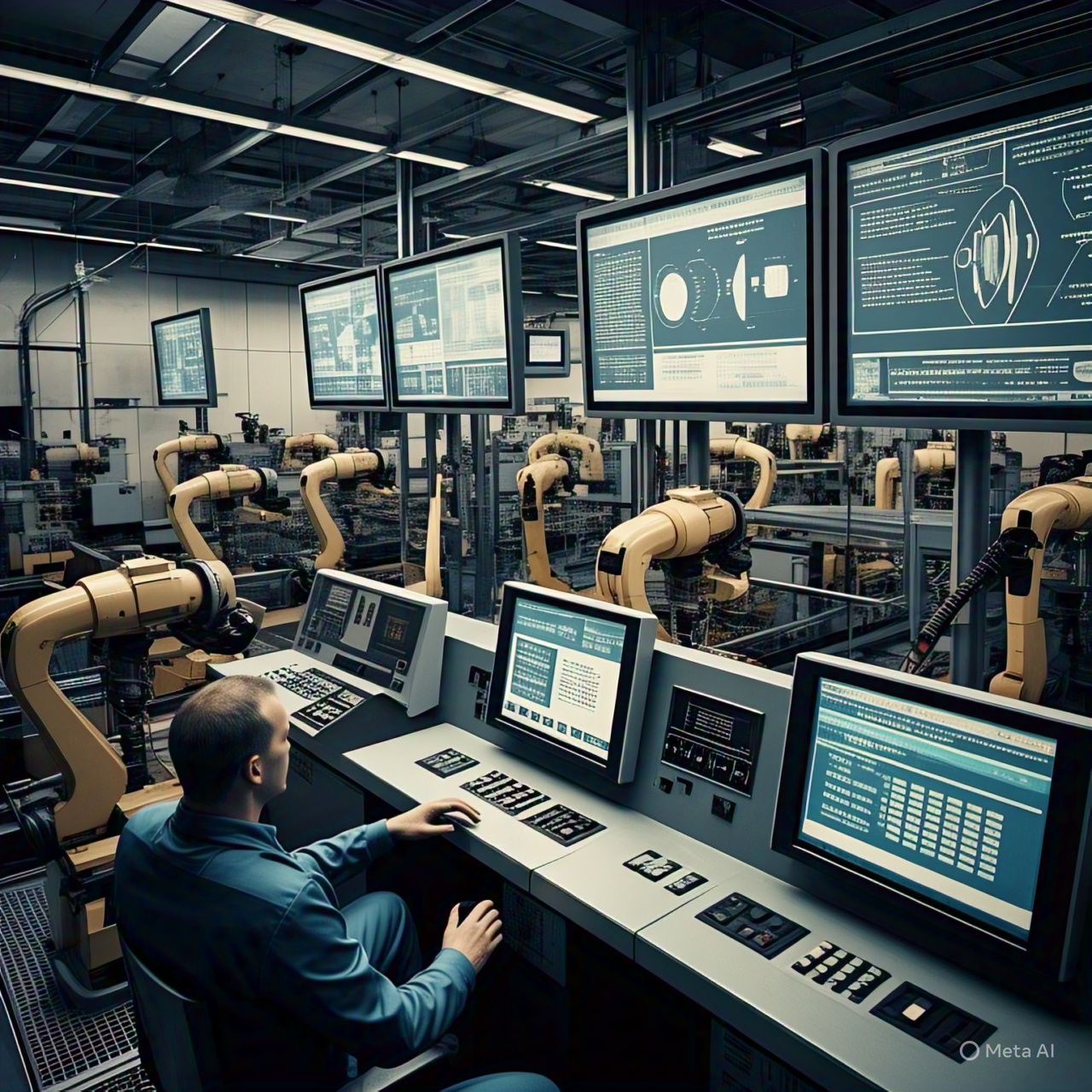

1. Industrial Internet of Things (IIoT) and Manufacturing

-

monitoring the machine’s vibration, temperature, and uptime.

-

Equipment failure is decreased with predictive maintenance.

-

alerts oneself to any problems that may arise along the logistics of the supply chain.

2. Buildings and Homes with Intelligent Systems

-

The Internet of Things (IoT) monitoring software checks the temperature, lighting, and occupancy.

-

lets people know when there’s energy waste, gas leaking, or unwanted visitors.

-

enables automated processes, such as turning off a room’s lights while nobody is in it.

3. Health Care

-

watches glucose meters and heart rate monitors, among other wearable medical devices.

-

ensures immediate data transmission to doctors for treatment and diagnosis.

-

keeps health and safety requirements in place.

4. Transport and Fleet Management

-

constantly monitors the driver’s actions, the engine’s efficiency, and the GPS data.

-

Automated identification of mechanical issues and changes in route in real time.

-

improves delivery times while making the most efficient use of gasoline.

5. Agriculture and Farming

-

makes use of IoT devices to monitor soil moisture, humidity, and temperature.

-

makes it possible to intelligently irrigate based on soil and weather data.

-

forestalls the destruction of crops caused by pests and other environmental factors.

The Efficiency of IoT Monitoring Software

-

Automates frequent checks, reducing the need for human inspections.

-

Safety: Quick identification of Internet of Things (IoT) device security issues.

-

Economical: minimizes wastage and keeps costly downtime to a minimum.

-

Flexibility: Easily grows to monitor thousands of devices in different locations.

-

Personalization: Users have the ability to design their own reports, alarms, and thresholds according to their needs.

Contribution to Enhancing IoT Security

IoT monitoring software plays a significant role in keeping networks clean.

-

keeps an eye out for suspicious behavior on connected devices that can indicate a cyberattack.

-

warns users if their network is attempted to be joined by an unknown device.

-

helps businesses comply with regulations governing cybersecurity, including GDPR and HIPAA.

Performance Capabilities

-

Time to response, latency, battery life, and data transfer rate are some of the metrics tracked by monitoring.

-

compiles reports detailing past events for the purpose of trend analysis.

-

permits future issue prevention via forecasting powered by machine learning.

Interoperability with Other Platforms

Most programs have little trouble establishing connections with:

-

platform for the cloud (Google Cloud, Azure, and Amazon Web Services)

-

ERP and CRM software

-

Access points for third-party APIs

Integrating existing business systems increases their value.

Artificial Intelligence and Machine Learning

-

useful tools for identifying patterns and predicting problems.

-

reduces the number of false positives while simultaneously increasing the accuracy of alerts.

-

continually learns from and improves upon its own past actions.

Possible Deployment Choices

-

Businesses that deal with sensitive information will find on-premise solutions ideal.

-

The cloud allows for scalability and connectivity from anywhere.

-

Mixes the best features of both on-premises and cloud computing to create a hybrid system.

Human-Computer Interaction and Design

-

In order to make judgments fast, dashboards must be clear and simple to use.

-

Thanks to mobile compatibility, users have the freedom to monitor from anywhere.

-

Systems designed for enterprise usage often support several languages and users.

Examining Past and Present Data

-

Instantaneous: Prevents emergencies by reacting to current situations in real time.

-

For the past, it keeps tabs on how things have been doing and makes optimization and auditing easier.

Common Applications for Internet of Things (IoT) Tracking

-

You may use Thing Speak for schoolwork or playtime; it’s an open-source platform.

-

Data dog IoT: Offers scalable metrics, logging, and device monitoring.

-

Azure IoT Hub is the name of Microsoft’s enterprise-level Internet of Things monitoring solution.

-

Protect your devices, keep them in the loop, and manage them all using AWS IoT Core.

-

Bosch IoT Suite: Engineered for usage in manufacturing and transportation.

Applying Statistics in Everyday Life

-

Forecasts indicate that 75 billion IoT devices will be operational by the year 2025.

-

The majority of businesses (almost 60%) think that monitoring software is crucial for the Internet of Things to be successful.

-

Companies using Internet of Things (IoT) monitoring in real-time are three times more likely to prevent outages.

Common Difficulties and Solutions

-

Eliminate Data Overload by Utilizing Dashboard Filters and Prioritization Tools.

-

Reduce latency by using apps that make use of edge computing.

-

Make that the software can communicate with your device’s protocols.

-

Protect sensitive information with end-to-end encryption and role-based access controls.

Smart City IoT Monitoring

-

Keeps tabs on utilities, public lighting, traffic, and trash pickup.

-

helps city planners by showing how infrastructure is being used and how populations are changing.

-

Improved emergency response is made possible by real-time alerts sent by IoT monitoring software.

Customizing to Specific Requirements

-

Kinds of alerts, reporting schedules, and key performance indicators are all up for grabs for businesses.

-

establishes novel interfaces with preexisting legacy systems.

-

There are a variety of personalized branding choices available to OEMs and MSPs.

Data Collection and Storage Options

-

work with SQL, NoSQL, and time-series databases.

-

offers data backup automated backup and disaster recovery services.

-

Data lakes and warehouses may be connected for in-depth analysis.

Environmental Monitoring

-

Stay up-to-date on water use, temperature, and carbon footprint with environmental monitoring.

-

used in eco-conscious businesses and sustainable building projects.

-

Software for Internet of Things (IoT) monitoring helps in maintaining sustainability goals.

Test and Simulation Characteristics

-

Devices may be tested in sandboxes before they are deployed.

-

reproduces the actions of loads and networks under different conditions.

-

makes the system safer before it’s put into action.

Stakeholders and Use

-

Information Technology (IT) Teams: To guarantee device health and uptime.

-

Increasing efficiency and output is a top priority for operations managers.

-

Chief Information Officers and Chief Technology Officers: For purpose of system growth and future planning.

-

Building automation and security are the responsibilities of facility managers.

Concerning Legal Matters and Conformity

-

Secure handling of IoT data is mandated by the CCPA and GDPR.

-

A number of countries mandate the registration and monitoring of all electronic devices.

-

Internet of Things (IoT) monitoring software makes it easier to maintain track of inspection and audit data.

Redundancy and Backup

-

ensure that data remains intact even in the face of disruptions.

-

has the capability to mirror to backup servers instantly.

-

crucial for industries including healthcare, banking, and aviation.

Relevance on a Global Scale

-

It is used by multinational organizations to manage devices on many continents.

-

helps to ensure compliance across borders and supports interfaces in several languages.

-

The use of real-time alerts helps combat the effects of different time zones in cross-border activities.

The Impending Future of IoT Monitoring Software

-

Predictive analytics will become the norm, replacing reactive monitoring.

-

More and more technologies will employ augmented reality (AR) for monitoring in the field.

-

5G networks will speed up data collection and processing.

-

More and more attention will be paid to the responsible use of data and ethical AI.

Final Thoughts: The Value of Internet of Things Monitoring Tools

As the number of interconnected devices grows, robust monitoring solutions are becoming increasingly important.

Security, performance, and stability are guaranteed by Internet of Things monitoring software, whether it’s used to control smart homes or industrial operations.

Companies risk losing data, experiencing security breaches, and inefficient operations if they do not have it.

It used to be a nice-to-have, but today it’s an essential tool for digital transformation.